Puppy Prosthetic

Prosthetics are a growing technology that allow those with missing limbs to continue to live their lives normally. Prosthetic limbs and body parts can range from simple to complex and are composed of all different materials.

The Enable Community Foundation (ECF) volunteers to 3D print and donate prosthetics to children. These prosthetics are 3D printed using CAD software, 3D printers, and different types of plastic.

Animals all over the world require the use of prosthetics to function in everyday activities. More specifically, a four-year-old German Shepherd-Lab Mix named Kara had her right hind leg amputated when she was a puppy due to abuse and injury. Daily activities are quite difficult due to only having three legs; Kara struggles to walk and run, while also having pain and exhaustion from using her other limbs to compensate for her loss. While prosthetics are used to help people, their assistance to animals has grown within the past few years.

A multidisciplinary team of engineering students at Rochester Institute of Technology is teaming with the ECF to design, model, test, and 3D print a prosthetic leg for Kara so that she can perform all of the activities that every dog should be able to do with ease. With this solution, the dog’s quality of life will improve, as will her owner’s. In the future, this project will expand those that will be helped by the ECF, as well as expand the possibilities of 3D printing and prosthetics.

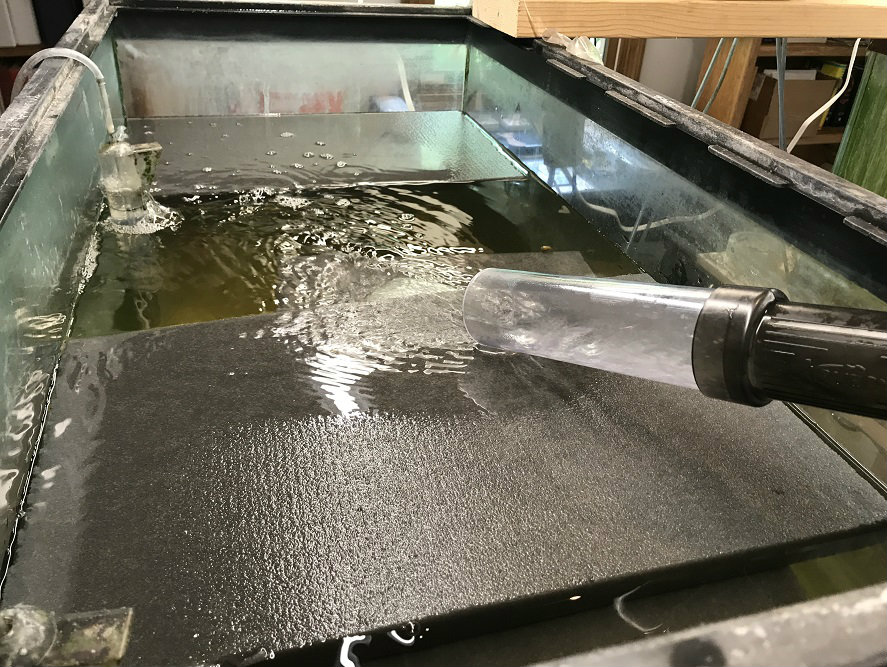

The first step of this project was for the team to meet Kara, observe her movements, and take foam impressions of her residual limb. After researching multiple types of foam, we found an impression foam produced by Smithers Oasis Engineered Products that is used frequently in the orthotics industry. After contacting the company, Smithers Oasis Engineered Products sent 12 foam impression kits to our project team. We used the foam to obtain impressions of Kara’s residual limb and had great success. The foam was easy to use, provided us with a precise shape of Kara’s leg, and did not require too much pressure to obtain an impression. Using these impressions, we were able to 3D scan and 3D print a prototype of Kara’s leg that we can use to fit our prototypes to before we test them on her. This will allow us to create several iterations of prosthetic designs in order to reach a final design that will work best to help Kara and improve her life.